One priority: recycling

The project’s water requirements have been estimated at 1.2 million m3 (600,000 for concentration and pipeline transport, and 600,000 for conversion). 90% of that water will be recycled.

Precise knowledge of water behaviour

Since 2022, a number of investigative surveys have been carried out on the La Bosse massif to gain a better understanding of groundwater and surface water behaviour and quality. They are based on over 70 measuring points spread over the massif (most of them via piezometers). This data is used to assess the potential impact of the mine on both quantity and quality. Initial results show that the granite to be mined is practically impermeable. The impact of mining operations should thus be limited.

Withdrawals that conserve groundwater

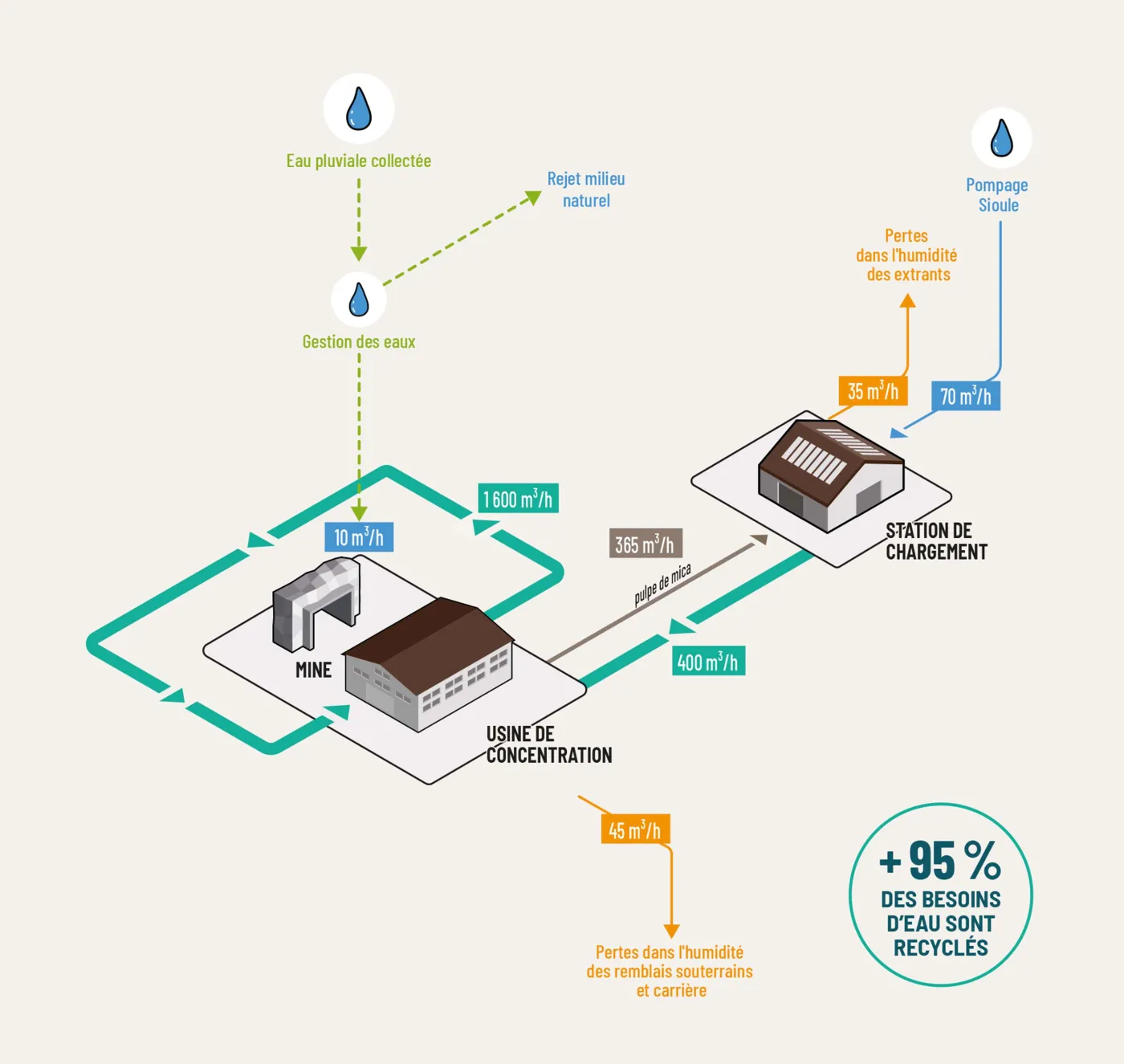

Other studies have identified potential water sources. For the concentration plant, Imerys has chosen not to draw on groundwater but on the Sioule river. The water drawn from the river will amount to 0.6% of flow at the lowest water level over an average of five years. In the event of drought, other solutions may be implemented, such as the creation of water reserves on the Beauvoir site.

Simplified water balance for the mill

Innovative solutions for the conversion plant

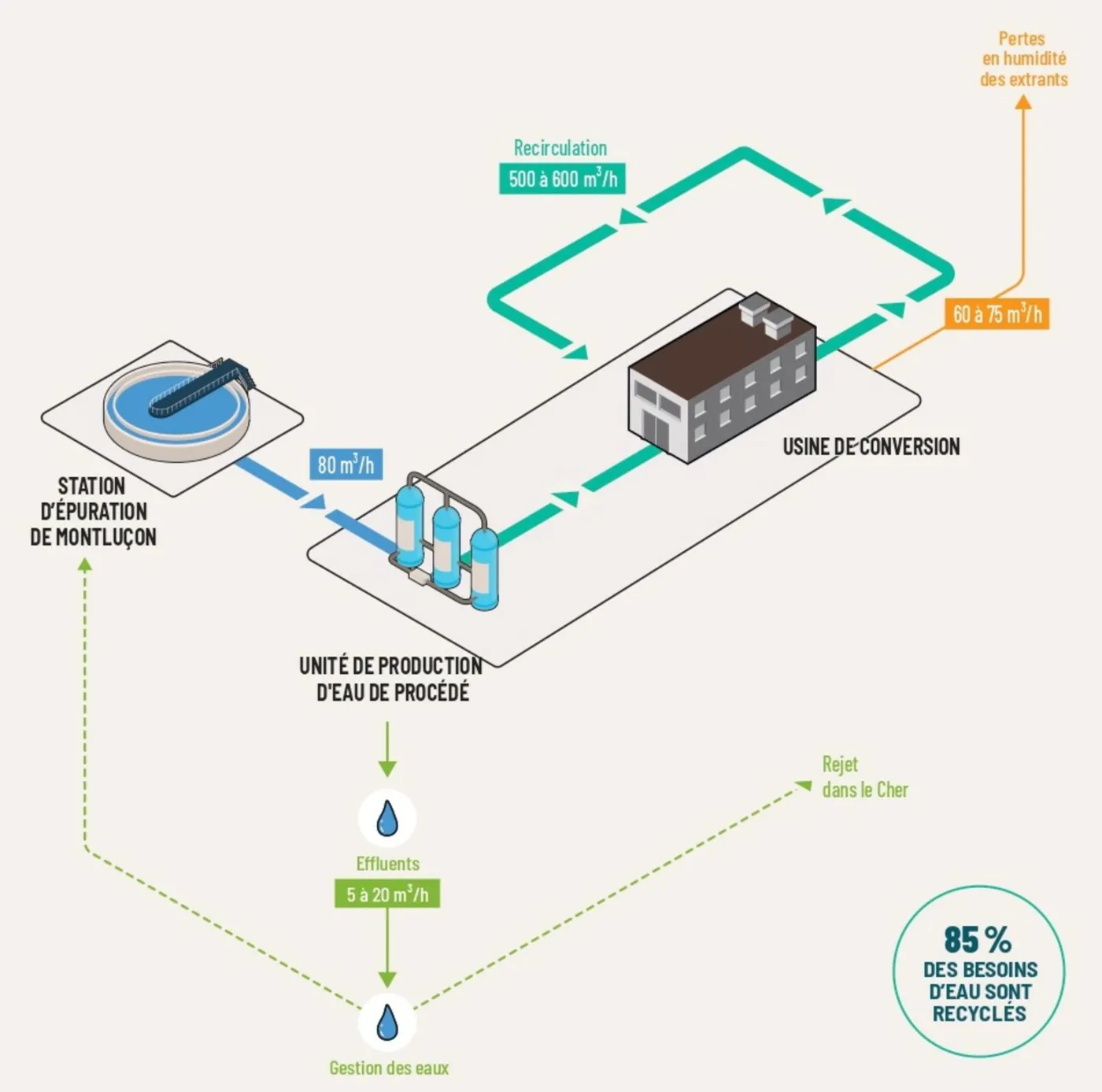

The Montluçon conversion plant will be supplied with treated water from the nearby wastewater treatment plant (around 10% of the plant’s output). This technical solution means that no water will be drawn from the Cher.

In addition, we have opted for an innovative Zero Liquid Discharge (ZLD) solution to treat and recycle all liquid effluent from the conversion activity. During several stages (osmosis, evaporation, crystallisation, etc.) the water is separated from other solid elements and purified. All is then recycled. This solution avoids any liquid discharge.

Simplified water balance for the conversion plant

Water in numbers

Storage

Storage capacity on the Beauvoir site

Distribution

Water needed to produce 1 tonne of lithium hydroxide

Concentration

Water needed for concentration / 95% from recycling

Your questions about water

How will you manage your water supply for the processes when you come on stream?

The total volume in the 10-15 cm diameter underground pipes over a dozen kilometres between the Beauvoir site and the loading station, as well the volume for the retention basin, flotation cells and decanters, is marginal and thus does not require significant initial filling.

The net volume of water required each year to offset the moisture contained in the lithiniferous micas sent to the conversion site is directly related to the output of the Beauvoir mine (and not to the capacity of the pipes).

Given the gradual ramp-up of the mine when it starts operations, the net water requirement in the first few years should logically be lower than the 600,000 m3 indicated.

With regard to your water requirements, what quantities of water will be circulated in your processes at the concentration and conversion stages?

It has not yet been possible to estimate the volume of water circulating in the conversion plant, but it will probably be less than the volume for concentration, at a flow rate of 500/600 m3/h.

Will there be any heavy metals in the quarry (heavy minerals)?

Tin, and possibly tantalum, extracted from the granite will be concentrated and recovered.

Arsenic concentrations are very low (approximately 0.002%).

How will any mine water be managed?

Could explosives in the mine increase crack permeability and make the water table more vulnerable to surface pollution?

Will this project use chemicals that will pollute the water?

At the conversion site, Zero Liquid Discharge (ZLD) technology will mean that no water will be discharged directly into the natural environment (except for one-off needs, in which case the effluent would treated before discharge).

What impact will arsenic and lead pollution have on water quality?

Arsenic and lead are naturally present in groundwater within micaschists. Their presence has been known for a long time. Drinking water in the towns concerned is drawn from elsewhere.

The mine will be dug in granite, where arsenic levels are very low, reducing the risk of arsenic remobilisation.