EMILI, a key project for the energy transition and European sovereignty

In a context of energy transition, lithium has become critical to the development of low-carbon mobility. But lithium supply is a key issue. To date, lithium production is highly concentrated in three non-European countries: Australia, Chile and China, which also manufactures 79% of batteries.

The current geopolitical crises show that it is risky to depend solely on foreign sources of supply for critical materials. This situation presents risks for manufacturers, who are in a situation of dependence. Environmental issues also need to be taken into account in order to implement more respectful practices when launching new mines.

Global demand for lithium has doubled over the last ten years. Driven by the transition to electric vehicles, global consumption of this metal is expected to increase 42-fold by 2040 compared with 2020 (International Energy Agency).

The EMILI project is based on a lithium deposit located in the Allier region, next to a kaolin site that has been mined since the mid-19th century.

EMILI would be the first project to open a lithium mine in France, producing 34,000 tonnes of lithium hydroxide a year - the equivalent of 700,000 electric vehicles fitted with lithium-ion batteries a year.

Projects in France

In France, 7 exclusive research permits (PER) for mines including lithium have been issued (with extraction characteristics specific to each project):

- The PER known as the ‘Beauvoir permit’ (EMILI project) ;

- Three PERs located in Bas-Rhin (‘outre-forêt lithium permit’, ‘Illkirch lithium permit’ and ‘les sources alcalines’);

- Three PERs located in Haute-Vienne (‘Douillac’, ‘Fayat’ and ‘Pierrepinet’).

Eight other PERs including lithium are currently being examined.

To remember

A large-scale project with a long-term impact on the region.

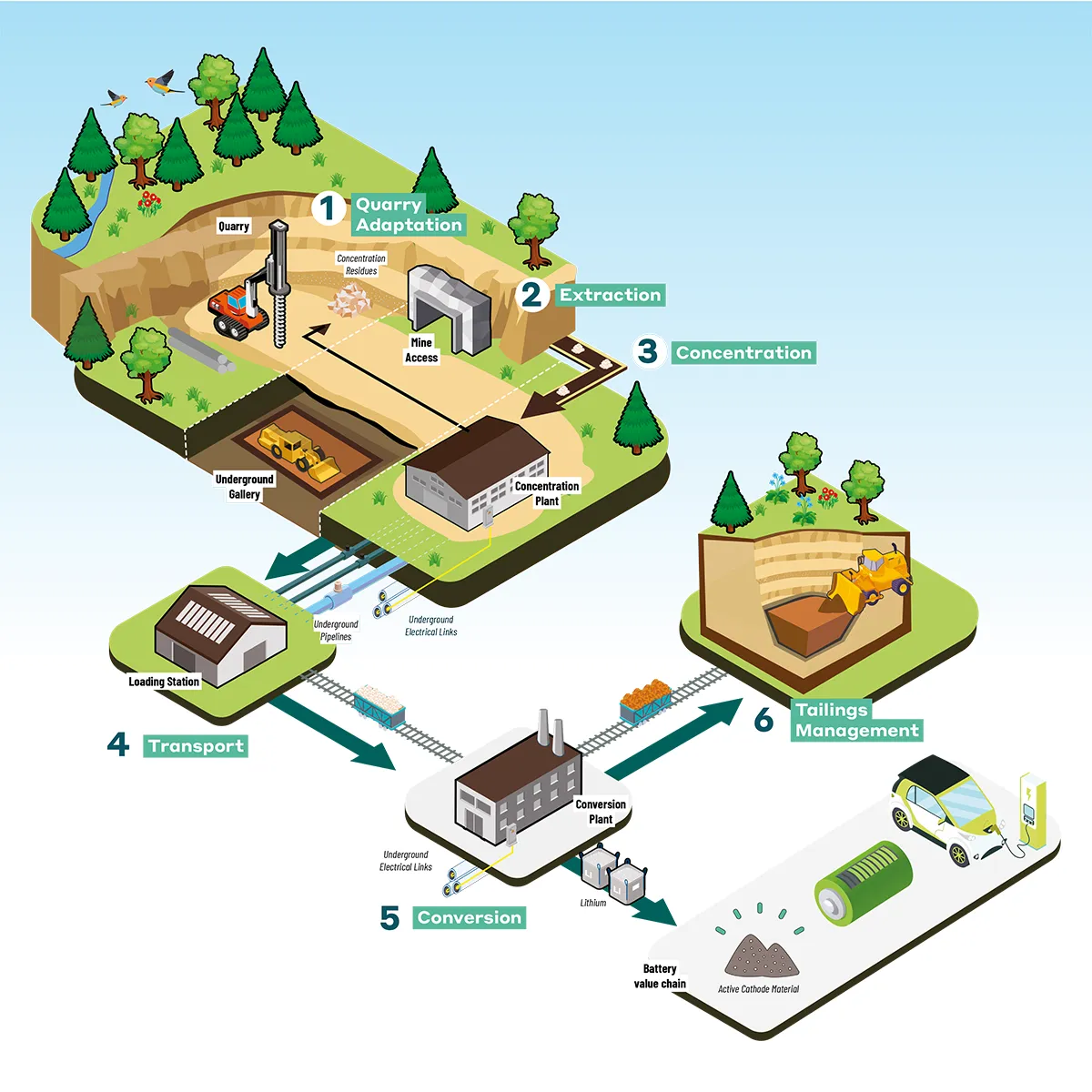

Several components, several locations

- An underground mine, under the Kaolins de Beauvoir quarry on the Bosse massif (a site already mined on the surface)

- A concentration plant, also on the Beauvoir site, to separate the minerals contained in the granite, which is the rock mineralised in lithium.

- A rail loading platform at ‘La Fontchambert’ (near Saint-Bonnet-de-Rochefort) or Vicq. The concentrate of the mineral, known as mica, would be brought there by pipeline and filtered before being loaded onto trains.

- A conversion plant on the ‘La Loue’ industrial estate (in the commune of Saint-Victor, near Montluçon), accessible by rail and with an annual production capacity of around 34,000 tonnes of lithium hydroxide.

With extraction and conversion all taking place within the same geographical area, this choice of short-loop management helps to reduce the project's carbon footprint while supporting local development.

EMILI project conceptual scheme

Strong, innovative choices

No industrial activity is neutral. But beyond compliance with the strictest international regulations and standards, the solutions developed and investments planned by Imerys place Emili among the most responsible industrial projects in the world.

‘The EMILI project is an essential lever in the electrification of mobility and the fight against global warming. We are acting for future generations. That's what all our teams are working on every day, together with all the government departments, local authorities and local residents’.

Alan Parte

VP Lithium Projects Imerys

The EMILI project in figures

Deposit

Number of tonnes of 0.9% lithium

Start of production

Year of commencement of production (for a farm at least 25 years old)

Jobs

Number of direct and indirect jobs created

Your Questions on the Project

What interest does Imerys have in becoming involved in IRMA?

Certification requires an audit by an independent third party, which must be repeated every three years in order to maintain certification.

In addition, the project leader’s report is published, whether or not the standard is obtained.

IRMA is thus a key tool for guiding Imerys in carrying out a responsible project.

Are there no alternatives to lithium technology, currently available or under development?

There is also a lot of talk about hydrogen. However, given the current state of knowledge, the physical properties of lithium make it an indispensable and, for the time being, irreplaceable metal on the industrial scale. Hydrogen currently remains an expensive and less efficient solution.

Has a mechanism been put in place to manage the relationship with stakeholders? Who will be the point of contact?

In addition, we have organised visits to the kaolin quarry for local councils, as well as various associations (opposed to the project or not), in line with our open approach.

The Group has also recruited two staff members dedicated to stakeholder relationship management. Their task is to keep stakeholders informed and gather requests and feedback to ensure the highest quality dialogue between Imerys and local stakeholders.

There is a complaints facility on the project website (emili.imerys.com) on the dialogue page and at the bottom of the contact form.